What We Do

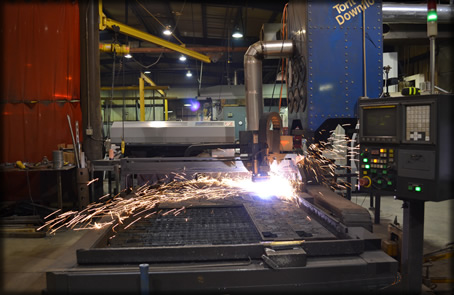

Cutting Capabilities

Laser Cutting

Our 4000-Watt lasers can quickly and accurately cut almost any type of material with a smooth, dross-free edge that requires little or no clean up. C02 laser-cutting technology has become the most cost-effective cutting method for many applications. For both short and long runs, lasers provide many real advantages. We use Mitsubishi Laser Cutters with a positioning tolerance of .00039 and repeatability of .00020. Our Laser Cutters are equipped with 5' x 10' and 6' x 12' tables which can accommodate large assemblies or produce multiple assemblies from a single sheet of raw material. With three fully operational laser cutters, we offer quick turn-a-rounds while ensuring the highest quality parts for our customers.

Our 4000-Watt lasers can quickly and accurately cut almost any type of material with a smooth, dross-free edge that requires little or no clean up. C02 laser-cutting technology has become the most cost-effective cutting method for many applications. For both short and long runs, lasers provide many real advantages. We use Mitsubishi Laser Cutters with a positioning tolerance of .00039 and repeatability of .00020. Our Laser Cutters are equipped with 5' x 10' and 6' x 12' tables which can accommodate large assemblies or produce multiple assemblies from a single sheet of raw material. With three fully operational laser cutters, we offer quick turn-a-rounds while ensuring the highest quality parts for our customers.Waterjet Cutting

Waterjet Cutting Technology is a computerized cold-cutting technology that can cut most materials into any two-dimensional shape. Our system will precision cut materials such as carbon steel, stainless steel, aluminum, titanium, stone, glass and plastic up to six inches thick at a tolerance of plus or minus .005 or better. We can create parts, signs, art pieces, architectural applications; in fact, anything that can be drawn on a computer can be cut using our waterjet cutting system on the 6' x 12' table.

Waterjet Cutting Technology is a computerized cold-cutting technology that can cut most materials into any two-dimensional shape. Our system will precision cut materials such as carbon steel, stainless steel, aluminum, titanium, stone, glass and plastic up to six inches thick at a tolerance of plus or minus .005 or better. We can create parts, signs, art pieces, architectural applications; in fact, anything that can be drawn on a computer can be cut using our waterjet cutting system on the 6' x 12' table.Plasma Cutting

Fabrication

Precision Machining

Laser Fabrication & Machine offers both conventional and advanced CNC milling services. Our skilled machinists produce a broad range of parts from the exotic and complex, to simple, quick-run pieces. We specialize in manufacturing small and medium run batches but are capable of producing at almost any scale. Laser Fabrication and Machine offers both build to print and build to specification manufacturing services. We are committed to producing parts that meet your requirements.

Laser Fabrication & Machine offers both conventional and advanced CNC milling services. Our skilled machinists produce a broad range of parts from the exotic and complex, to simple, quick-run pieces. We specialize in manufacturing small and medium run batches but are capable of producing at almost any scale. Laser Fabrication and Machine offers both build to print and build to specification manufacturing services. We are committed to producing parts that meet your requirements.

Our machine shop is equipped with two Haas CNC vertical milling centers – VF-7/50 and VF-6/50 – both capable of a variety of milling functions and each outfitted with a 30+1 side-mount tool changer. Laser Fabrication & Machine also has two CNC lathes, an Okuma with a 12-tool turret and a 2-7/8” bore Space Saver 2000 bar feed and a Haas which has a 12-tool turret and 3” bar capacity.

Precision Forming Services

Laser Fabrication & Machine has extensive metal forming capabilities using our press brake equipment. Our facilities are equipped with five CNC press brakes which range from a small 40-inch model up to a 13-foot brake with a press capacity of 35 to 300 metric tons.

Our press brake equipment includes a Toyokoki HYB-85, with a 93.5 ton press capacity and a 95.5” table, a Diamond BB 4013, 40 ton x 4' Electric Press Brake with a 49.6” table, a Diamond BH “Dual Drive” BH 1353, 149 ton with a 10' bending table Press Brake, and a 330 ton Diamond Elite 30040 brake press with a 159 inch bending capacity.

CNC Rolling Capabilities

Laser Fabrication & Machine has extensive plate and profile bending capabilities. Our facilities are equipped with an IMCAR 3RHT Hydraulic Plate Roll which allows us to pre-bend both ends of the plate like a four roll machine but offer additional advantages and features. Both side (lateral) rolls move horizontally and independently from one another with variable pitch, while the top roll also moves up/down vertically. This geometry employs the best features of 4 roll double pinch, Initial pinch and pyramid geometries. The top rolls interchange to increase plate range of plate bending and produce optimal cone rolling results.

Laser Fabrication & Machine has extensive plate and profile bending capabilities. Our facilities are equipped with an IMCAR 3RHT Hydraulic Plate Roll which allows us to pre-bend both ends of the plate like a four roll machine but offer additional advantages and features. Both side (lateral) rolls move horizontally and independently from one another with variable pitch, while the top roll also moves up/down vertically. This geometry employs the best features of 4 roll double pinch, Initial pinch and pyramid geometries. The top rolls interchange to increase plate range of plate bending and produce optimal cone rolling results.

Our facilities are equipped with an Eagle Full CNC section profile bending roller. The Eagle BA Series Roll Benders produce parts in one pass using the hydraulic powered lower bending roll which moves upward toward the top roll to create the desired radius. This Initial Pinch design maintains in-feed material stock parallel to the shop floor for reduced material handling and enhanced safety.

Our facilities are equipped with an Eagle Full CNC section profile bending roller. The Eagle BA Series Roll Benders produce parts in one pass using the hydraulic powered lower bending roll which moves upward toward the top roll to create the desired radius. This Initial Pinch design maintains in-feed material stock parallel to the shop floor for reduced material handling and enhanced safety.

Manufacturing

COMPLETE MANUFACTURING SOLUTIONS

Laser Fabrication & Machine is a full-service engineering, prototyping, machining, manufacturing and fabrication facility. Utilizing state-of-the-art equipment and fabrication techniques, our highly-skilled staff can provide cost-effective solutions for your fabrication and manufacturing needs. Because both conventional and specialized fabrication are needed to meet most customers’ specifications, Laser Fabrication & Machine maintains a full-service fabrication and manufacturing facility. Our diverse capabilities and equipment enable us to maintain complete control of the production of your pieces. Our experienced quality control personnel utilize the latest inspection equipment to ensure consistency In meeting your specifications and aesthetic demands. We are committed to providing you with uncompressed performance, service and results.

ENGINEERING

Our engineering team can take your concept into the design phase to create a working prototype and deliver a finished product that will meet your developmental objectives. We use the latest manufacturing and design software, which coupled with our technical expertise, assures the very best in design-for-manufacturability assistance. Our engineering team is proficient in the use of programs such as Autodesk Inventor, AutoCad, SolidWorks, Metacam Advanced Fabrication and many other industry standard applications. We can take your artwork, blueprints, CAD files or technical specifications, and determine the best and most cost-effective approaches to create your product.

Our engineering team can take your concept into the design phase to create a working prototype and deliver a finished product that will meet your developmental objectives. We use the latest manufacturing and design software, which coupled with our technical expertise, assures the very best in design-for-manufacturability assistance. Our engineering team is proficient in the use of programs such as Autodesk Inventor, AutoCad, SolidWorks, Metacam Advanced Fabrication and many other industry standard applications. We can take your artwork, blueprints, CAD files or technical specifications, and determine the best and most cost-effective approaches to create your product.

PROTOTYPING

We work with you from concept to working prototype using your artwork, blueprints, CAD files and technical specifications. Our team of experienced engineers work with you to determine the best and most cost-effective approach to create your product.

We work with you from concept to working prototype using your artwork, blueprints, CAD files and technical specifications. Our team of experienced engineers work with you to determine the best and most cost-effective approach to create your product.

“I would whole-heartedly recommend Laser Fabrication, their products and their people to anyone needing fabrication or proto typing services.” Eddy Shipman, ZIP CYCLE.”

Military Support

SPARK II Mine Roller

Laser Fabrication and Machine provides support to the U.S. Military and produces fabricated parts for various tactical wheeled vehicles. We produce a version of the Self-Protection Adaptive Roller Kit (SPARKII) which can be used on vehicles such as the MRAP, Buffalo and similar military vehicles. The modular mine roller system is designed to be mounted on tactical wheeled platforms and forces as much of the blast down and away from the vehicle as possible, as opposed to underneath the vehicle.

Laser Fabrication and Machine provides support to the U.S. Military and produces fabricated parts for various tactical wheeled vehicles. We produce a version of the Self-Protection Adaptive Roller Kit (SPARKII) which can be used on vehicles such as the MRAP, Buffalo and similar military vehicles. The modular mine roller system is designed to be mounted on tactical wheeled platforms and forces as much of the blast down and away from the vehicle as possible, as opposed to underneath the vehicle.

Buffalo Mine Protected Vehicle

We also produce window covers, fenders and other fabricated components for the Buffalo Mine Protected Vehicle. The Buffalo is six wheeled tactical platform which is fitted with a large articulated arm, used for ordnance disposal. The Buffalo vehicles incorporate a “V” shaped monohull chassis that directs the force of the blast away from the occupants. Laser Fabrication and Machine is proud to produce accessories for our U.S. military customer.

We also produce window covers, fenders and other fabricated components for the Buffalo Mine Protected Vehicle. The Buffalo is six wheeled tactical platform which is fitted with a large articulated arm, used for ordnance disposal. The Buffalo vehicles incorporate a “V” shaped monohull chassis that directs the force of the blast away from the occupants. Laser Fabrication and Machine is proud to produce accessories for our U.S. military customer.

BAE Systems RG33 MRAP

Laser Fabrication and Machine provides up-armor plating to support the MRAP variant which was produced by BAE Systems. The BAE MRAP RG33 series is in the medium weight class unit, providing survivability, advanced mobility, mission flexibility, rapid availability and vehicle commonality.

Laser Fabrication and Machine provides up-armor plating to support the MRAP variant which was produced by BAE Systems. The BAE MRAP RG33 series is in the medium weight class unit, providing survivability, advanced mobility, mission flexibility, rapid availability and vehicle commonality.

Chemical Agent Resistant Coating (CARC) Painting

We have the capability to paint using Chemical Agent Resistant Coating (CARC) for our U.S. military customer. CARC is the camouflage paint used on United States Army and Marine Corps tactical vehicles and equipment is applied to items we fabricate, such as the SPARK II modular mine roller system, window covers, fenders and other fabricated components for the Buffalo Mine Protected Vehicle, and the up-armor kit for the MRAP.

T & T Transit Products

Wheelchair Accessibility Ramp

Wheelchair Accessibility Ramp. Complete, self-contained “drop-in” style plug and play design. One-touch, simple, quick safe and smooth operation without bus driver intervention. Hydraulic actuator rated for one million cycles. Installation at front or rear doors with a solid 4 to 1 and a new 6 to 1 slope chain drive. Contact us today for more information.

Wheelchair Accessibility Ramp. Complete, self-contained “drop-in” style plug and play design. One-touch, simple, quick safe and smooth operation without bus driver intervention. Hydraulic actuator rated for one million cycles. Installation at front or rear doors with a solid 4 to 1 and a new 6 to 1 slope chain drive. Contact us today for more information.

- No assembly or adjustments required

- Simple one-touch controls

- No safety belts or bars required

- Front or rear door placement

- Load tested at 2,800 lbs. minimum deflection

- Meets all ADA requirements

- Added safety with interface seams of 3/8" – 1/2"

- Replaceable or reusable non-skid platform

- 2? standard side rails

- No special tools required for manual deploy or stow

- Provides quick, safe and comfortable access

- Ramp usable at 0 – 14", curb height to bus floor

- Rugged, lightweight, all blended construction: stainless steel and aluminum materials used

- Standard stainless steel arms

- 200 Ibs. without rubber; total weight only 240 lbs.

- Cycle tested before shipment

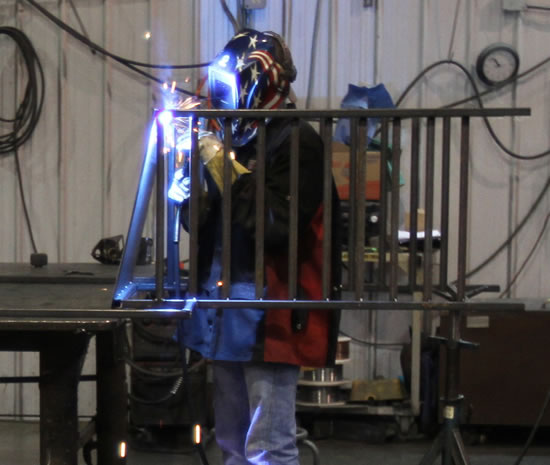

Welding

Laser Fabrication and Machine offers custom metalwork and fabrications services which can bring your manufacturing vision to life. We are equipped to handle almost any sort of metal work and have years of experience working with the following materials: aluminum, steel, stainless steel, brass, copper, and carbon steel. As well as solid pieces, we are experienced in working with both square and round tubing. If your project requires a creative mix of materials, don’t be afraid to ask. We have assembled combinations of ceramics, glass, and wood as well as metals.

Laser Fabrication and Machine offers custom metalwork and fabrications services which can bring your manufacturing vision to life. We are equipped to handle almost any sort of metal work and have years of experience working with the following materials: aluminum, steel, stainless steel, brass, copper, and carbon steel. As well as solid pieces, we are experienced in working with both square and round tubing. If your project requires a creative mix of materials, don’t be afraid to ask. We have assembled combinations of ceramics, glass, and wood as well as metals.

Laser Fabrication and Machine provides welding services for large industrial assemblies as well as intricate custom jobs. Our welders are certified under nationally recognized American Welding Society (AWS) standards, CWB (Canadian Welding Bureau) and have experience providing quality craftsmanship to meet your manufacturing needs. Our welding technicians are proficient in MIG, TIG and spot welding on carbon steel, stainless steel and aluminum. If you can dream it up, we can create it for you! Contact us today to get started.

Laser Fabrication and Machine provides welding services for large industrial assemblies as well as intricate custom jobs. Our welders are certified under nationally recognized American Welding Society (AWS) standards, CWB (Canadian Welding Bureau) and have experience providing quality craftsmanship to meet your manufacturing needs. Our welding technicians are proficient in MIG, TIG and spot welding on carbon steel, stainless steel and aluminum. If you can dream it up, we can create it for you! Contact us today to get started.